"District heating" asociado a generación de energía

District heating is one of the most common ways to supply heat for residential and commercial areas. It is also a great way to reduce carbon emissions while maintaining sustainable economic growth. Alfa Laval can help optimize district heating through solutions with high-efficiency fully welded plate heat exchanger condensers that reduce both plant footprint and operating expenses.

District heating reduces carbon emissions

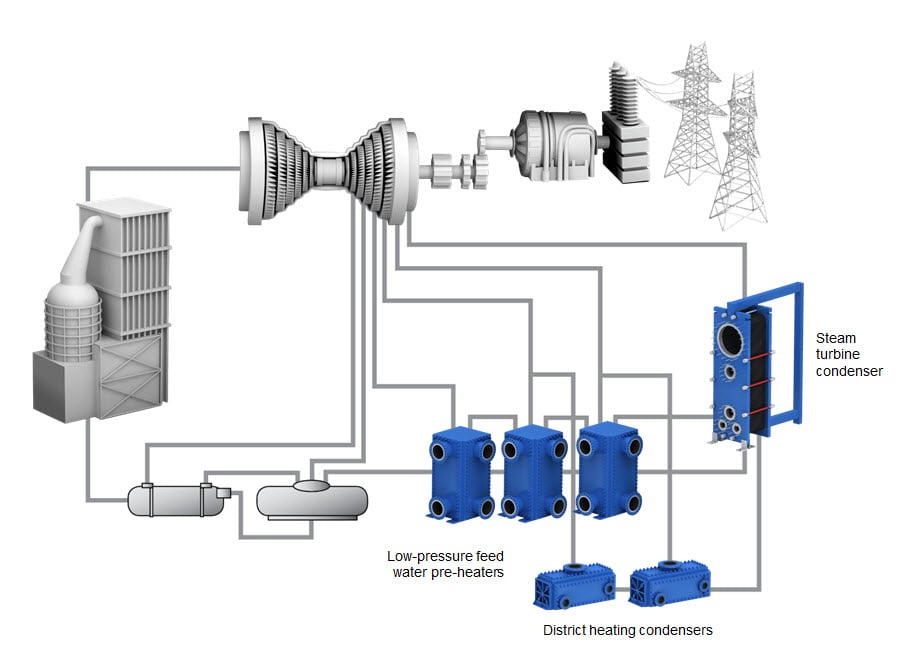

In a combined heat and power plant, one part of the extraction steam from turbine is used to supply heat for the district-heating network, which supplies our cities with hot water to heat up commercial buildings as well as our homes.

Combining district heating and electricity production in a combined heat and power plant is one of the most effective ways to reduce carbon emissions. Alfa Laval offers a wide range of products to increase efficiency throughout the entire network from the power plant to the substations.

High efficiency and small footprint

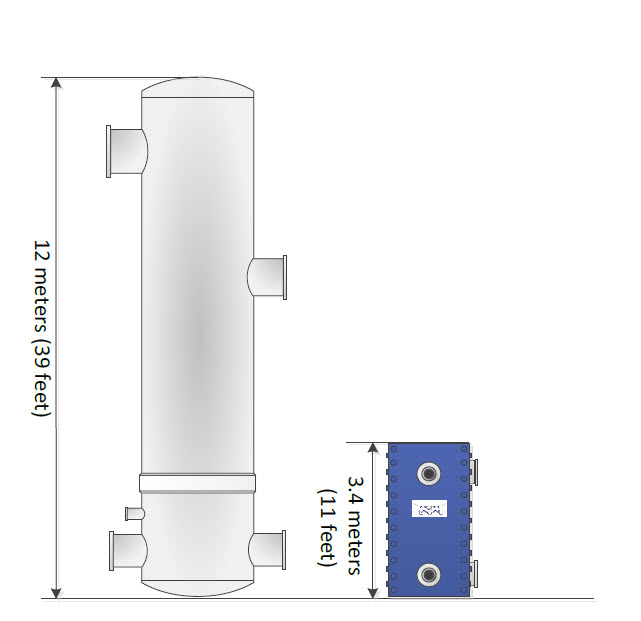

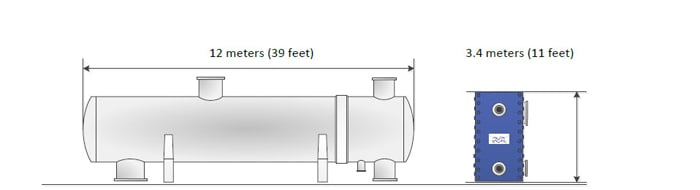

Increasing the overall efficiency of the main district heating plant depends upon the reliability and performance of its heat transfer equipment. Alfa Laval has vast expertise in optimizing compact, high-efficiency heat transfer equipment for district heating and power plants. Our welded plate condensers contribute to reduced operating expenses, significant savings on steam usage and less maintenance. Thanks to the high efficiency of our plate technology, the total footprint can be reduced down to 1/3 compared to traditional shell-and-tube heat exchangers. In addition, the requirements for a maintenance service area are virtually eliminated. Due to its compact size, Alfa Laval condensers can be placed on a single floor.

Made to last

Alfa Laval condensers can be supplied as single components or together with liquid level control system and filters. Equipped with AISI 316 stainless steel plate packs, Alfa Laval condensers withstand the harshest operating conditions.

Downloads

Process overview

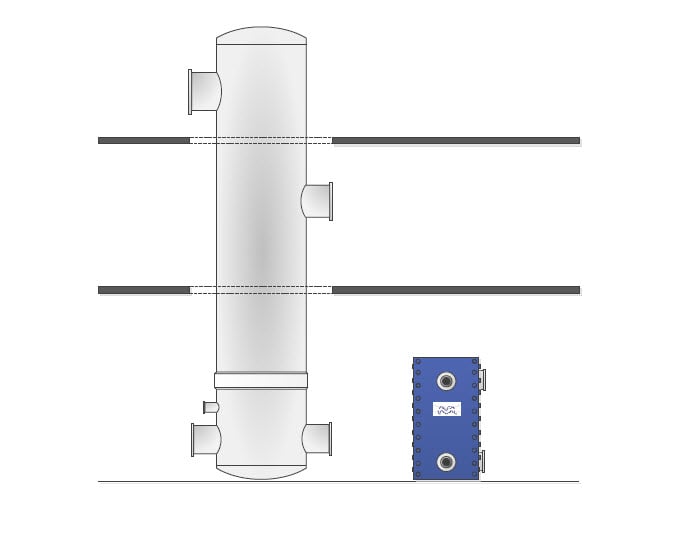

Compbloc VS shell-and-tube (same duty)

Compabloc VS shell-and-tube multiple floor installation