Benefits of plate technolgy

The choice of heat exchanger is very important and has a direct impact on your bottom-line results. In fact, replacing old shell-and-tubes with new compact heat exchangers in existing systems is often a very profitable investment.

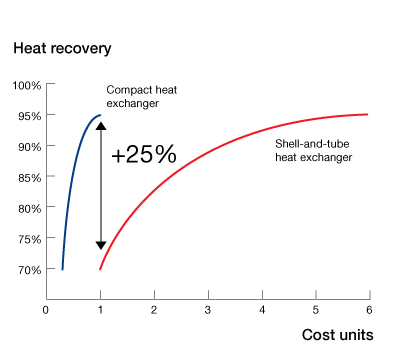

Heat recovery

The diagram shows the heat recovery level as a function of initial cost. The yield from compact heat exchangers is up to 25% higher than for shell-and-tubes at a comparable cost.

To reach the same levels of heat recovery, shell-and-tube solutions often become several times more expensive.

High turbulence

At the core of a compact heat exchanger is a set of heat-transfer plates with hot and cold streams flowing through alternate channels. The highly turbulent flow results in a substantially higher heat transfer efficiency than in a shell-and-tube, meaning compact heat exchangers operate with a 50-80% smaller heat transfer area.

Compact size

The small required heat transfer area means units are very compact and easy to install. This makes it easy to upgrade the capacity of existing systems. Exchanging shell-and-tubes for compact heat exchangers means you can fit in much higher capacity on the same floor space.

The small size is also beneficial from an investment perspective, especially when exotic materials are required. A compact heat exchanger needs less of the material, e.g. titanium, making it much cheaper than a shell-and-tube of the same material.

Superior heat transfer means a Compabloc is much smaller and lighter than a comparable shell-and-tube heat exchanger. The required installation space is minimal since no tube bundle needs to be extracted.

Crossing temperatures

The counter-current flow in most compact heat exchangers makes it possible to run a crossing temperature program in a single unit. With shell-and-tubes you need several heat exchangers in series for a crossing temperature program.

Product

Compabloc, Alfa Laval Compabloc welded heat exchanger is probably the most compact and efficient heavy-duty heat exchanger in the world.