Quench water coolers

Improve compressor capacity and reduce cooling water usage

The capacity of the compressor stage depends linearly on the temperature of the entering gas. The lower the temperature, the smaller the gas volume and the higher the compressor capacity.

The capacity of the compressor stage depends linearly on the temperature of the entering gas. The lower the temperature, the smaller the gas volume and the higher the compressor capacity.

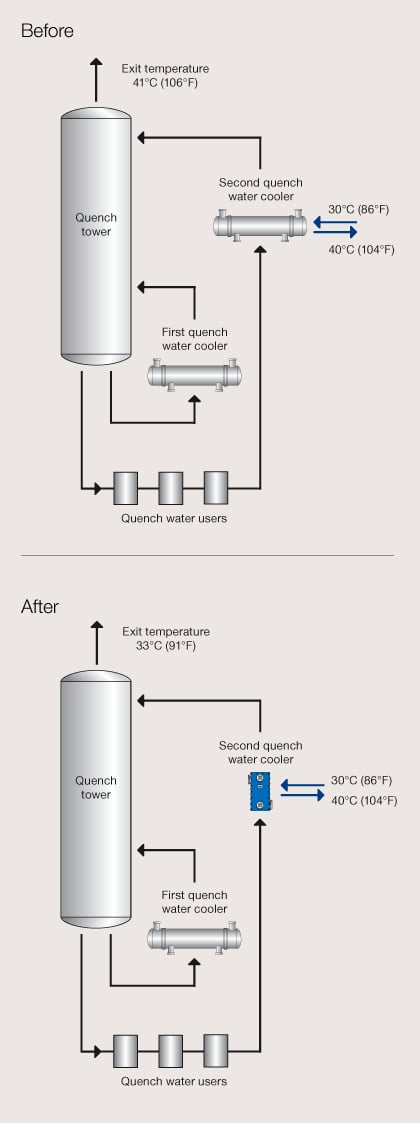

This means the temperature of the gas exiting the quench tower should be as low as possible. Improved cooling in the second quench water cooler is a straightforward way of achieving this. Exchanging an existing shell-and-tube in this position for a compact heat exchanger dramatically increases cooling, provided there are no limitations in cooling-water supply.

Example – second quench water cooler

A shell-and-tube operating as second quench water cooler cools quench water from 51°C (124°F) to 41°C (106°F) using cooling water with a temperature of 30°C (86°F). With the same cooling-water temperature, an Alfa Laval Compabloc cools the quench water 8°C (15°F) further – to 33°C (91°F).

This decreases the volume of the gas exiting the quench tower by 2.5%, thereby increasing the capacity by 2.5% in the first compressor stage.

Improved heat integration

It is always a good idea to find uses for heat instead of just cooling it off. It may also be a very effective way of resolving bottlenecks related to cooling-water usage.

The example above assumes there are no limitations in cooling-water flow rate or return temperature. Should this not be the case, you can fix the problem by improving heat recovery in positions using quench-water heat.

Heat from the quench tower is used throughout an ethylene plant, including various preheating positions. Using more efficient heat exchangers in these positions allows you to reuse more heat, thereby lowering the return temperature.

This means better heat exchangers in positions using quench-water heat lead to a lower need for cooling water in the quench water cooler.

By using a more efficient heat exchanger as second quench water cooler you lower the exit temperature from the quench tower and thereby increase the capacity of the first compressor stage.