Here for the beer: upcycling sustainable protein from brewer’s spent grain

Sustainable sources of high-quality protein are essential in meeting the ever-increasing global demand for healthy, affordable, and nutritious food. Alfa Laval’s expertise within protein makes it an ideal technology and solutions partner in this field.

DATE 2024-07-19

Innovation in this arena is exciting and fast-paced, and one of the latest newcomers to the market is a US-based business, which has not only developed a sustainable plant-based protein, but which uses a waste product from the brewing process as its feedstock.

EverGrain™, a wholly owned subsidiary of global brewing giant Anheuser-Busch InBev, has developed a cutting-edge process to extract high-quality protein isolate from spent grain from the beer brewing process.

The resulting product – EverPro® – is then sold as an ingredient to food companies for incorporation into a variety of products, including sports nutrition shakes and coffee drinks. Its high nutritional value, mellow taste and market-leading solubility in beverage application make it ideal for boosting the protein content across a range of consumer product categories.

“EverPro is a nutrient-dense plant-based protein, which is sustainably produced from Barley that is grown and made in the USA,” says Greg Belt, CEO of EverGrain. “It is completely water soluble with a clean taste, making it a very versatile ingredient and suitable for numerous products including ready-to-drink and ready-to-mix beverages, such as protein shakes and coffees, as well as smoothies and energy bars.”

And with sustainability at the core of its operation, EverGrain, is turning what was previously dried and sold as low-value animal feed into a sustainable source of high-quality, highly nutritious, plant-based protein.

“With this cutting-edge process, we can harvest barley’s hidden nutritional capacity – helping us serve up not just another protein, but a better protein,” says Steffen Muench, EverGrain’s Head of R&D. “And what’s more, through upcycling, we can do all this using the land we already have – not one extra acre is needed to utilize all the nutrients saved in barley for the good of people and planet.”

Commercial production of EverPro started in June this year at EverGrain’s brand-new facility in St Louis, Missouri, following years of research and development with industry and research experts.

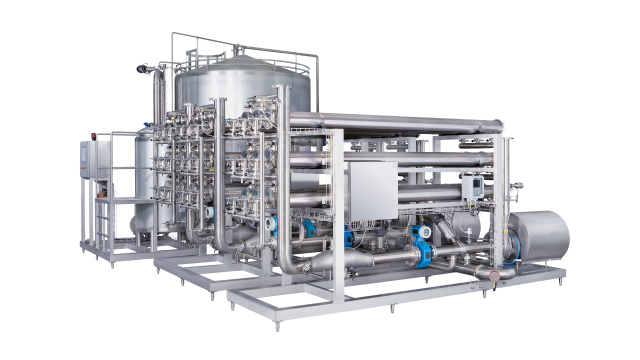

Separation and fluid handling technology for the installation has been supplied by Alfa Laval, which included six large decanters, reverse osmosis systems, valves, pumps, and tank cleaning equipment.

EverGrain has a continued high focus on process optimization and plans are in the pipeline for the construction of a pilot facility where improvements in overall yields will be developed alongside reductions in water use.

Finetuning is essential in the highly competitive protein isolate marketplace and Alfa Laval is well placed to provide EverGrain with technical expertise going forward, says David King, Food Separation Director for Alfa Laval in the US.”

“We have expert knowledge in separation, evaporation and membranes that goes back decades. We can help them to become as technologically advanced and commercially efficient as they can be and supporting them with our service reach and expertise around the world.

“This is just the start of their journey. The global reach of AB InBev means that EverGrain really does have the capacity to feed the world – taking an inedible waste product that was previously dried and sold as animal feed and turning it into quality protein.”

More about upcycling food by-products

Highlighted Technologies

Upcycling potential

Brewer’s spent grain accounts for up 85 percent of leftovers from the brewing process. According to one estimate, up to 20 billion pounds or approx. 10 billion kg of spent grain is produced as a by-product from beer production in the USA every year. It is essentially only the sugars in the grains which are spent during the brewing process, while remaining fibres, proteins and other nutrients can be extracted and converted into human food.

About EverPro®

EverPro, created by AB InBev’s sustainable ingredient company EverGrain, is the world’s first commercially available upcycled barley protein. EverPro was deliberately formulated and is scientifically proven to have unmatched solubility and viscosity levels compared to whey or pea and is at or above parity in absorption and digestibility. Makes it a great fit for sports and nutrition beverage applications. Because EverPro is made using a proprietary process to upcycle barley protein from brewer’s spent grain (BSG), it emits lower carbon and uses significantly less land and water, it is one of the most sustainable proteins on the planet and is certified by the Upcycled Food Association. EverPro’s first ever large-scale facility came online June of this year in St. Louis, MO.